| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Shitan

Model Number : ST-1000

Place of Origin : Hebei China

MOQ : 1 set

Price : 35000 USD-45000 USD

Payment Terms : T/T, Western Union

Supply Ability : 2000 sets/month

Delivery Time : 15-20 days

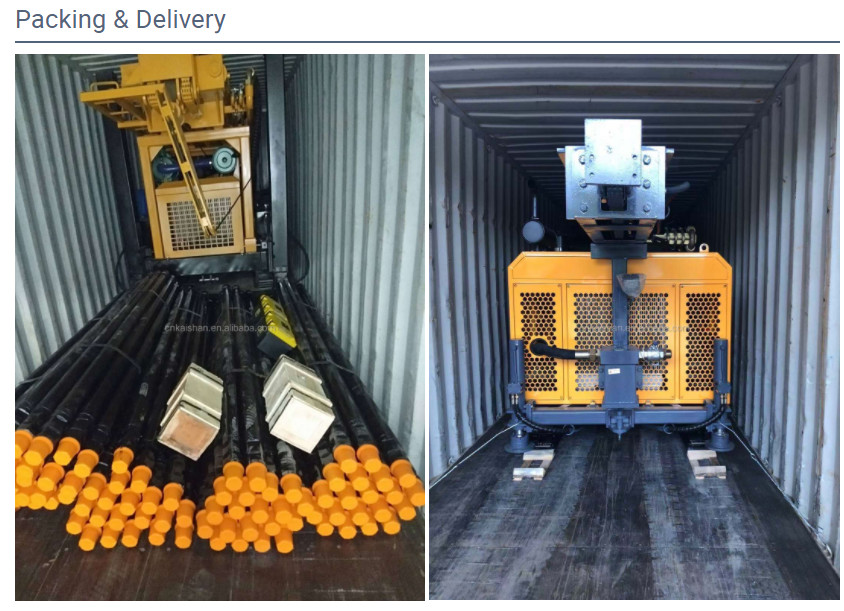

Packaging Details : Wooden box

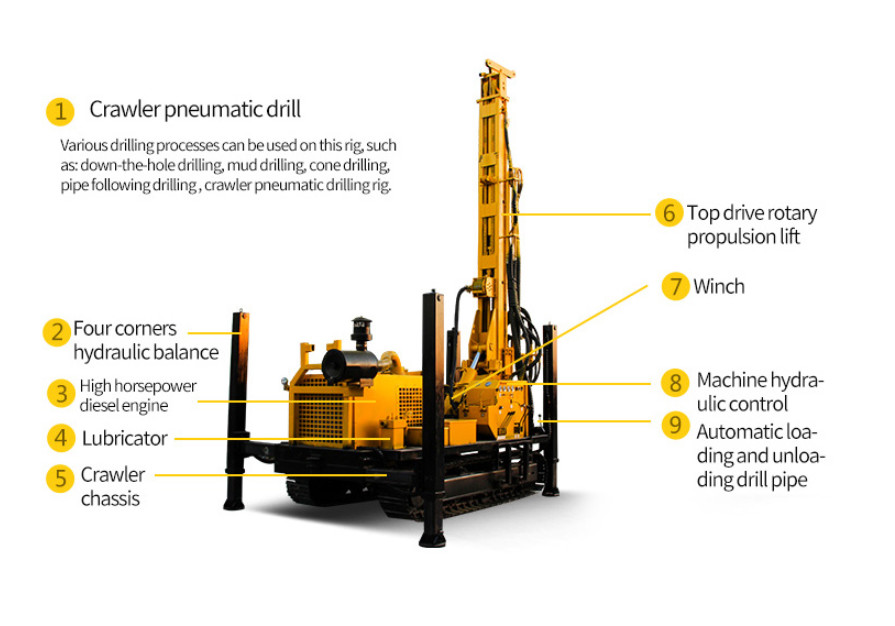

Product Name : High Drilling Speed ST 1000 Customized Pneumatic Borewell Machine Machines

Drilling depth : 1000m

Drilling diameter : Φ105-Φ500mm

One push length : 6M

Drilling pipe diameter : Φ102mm, Φ114mm

Iift force : 45T

Fast forward speed : 47m/min

Dimension : 6200x2200x2500mm

Weight : 18T

Diesel engine power : Cummins 242kw

Pneumatic ST1000 type water well drilling rig with fast drilling speed

ST 1000 Pneumatic Borewell Machine Main Technical Data:

| Model | Shitan ST 1000 | |

Max drilling depth | M | 1000 |

Drilling diameter | mm | 105-500 |

Air pressure | Mpa | 1.2-3.5 |

Rod length | m | 6 |

Rod diameter | mm | 102-114 |

Main shaft pressure | T | 6 |

Lifting force | T | 45 |

| Power head stroke | M | 47 |

Max rotary torque | Nm | 22000 |

Max rotary speed | r/min | 80-160 |

Secondary winch liftng force | T | 3 |

Jacks stroke | m | 1.5 |

Moving speed | km/h | 2.5 |

Uphill angle | Slope | 21° |

Weight of the rig | T | 18 |

| The engine | 242KW / 6 cylinder | |

Overall dimensions | 6200*2200*2500mm | |

Working condition | Loose layer and bedrock | |

Drilling method | Hydraulic rotary, down-the-hole impactor | |

ST 1000 Pneumatic Borewell Machine Main Advantages"

1. It improves drilling efficiency and reduces labor intensity With hydraulic automatic feeding mechanism.

|

|

High Efficiency Pneumatic Water Well Drilling Rig For Rock Layers Images |